Reducing Spend through Procurement Optimization

There’s nothing quite like the release of an innovative product. The anticipation, the suspense, and the pageantry are enough to keep the crowd on the edge of their seats. As a career-long manufacturing lead and product developer, I too love the release of the new products, but can’t help but think about all the grunt work that went on behind the scenes to get this product to market. Much of it wasn’t flashy, but was critical to driving the scalability and functionality of a sustainable new product. In much the same way, optimizing your organization’s procurement department probably won’t lead to a Netflix special, but is a critical workstream in maximizing gross margins and increasing overall valuation. We encourage organizations to Combine & Conquer, segmenting purchasing categories into a spend cube, re-negotiating larger, longer-term contracts, and optimizing the overall value chain from supplier to manufacturer.

DPO&Co founders cut their teeth in the procurement game and have now completed over 30 projects in the space. Our team of professionals combines deep industry knowledge in management consulting with a formalized process developed in the Procurement and Analytical Solutions (PAS) practice at A.T. Kearney. We recently completed one of these engagements at a firm undergoing a post-merger integration (PMI), eight months after the acquisition of a sizable add-on business unit. While the PMI process is particularly ripe for a procurement assessment, the steps we followed are relevant for any organization looking to reduce COGS and streamline their procurement team’s operations.

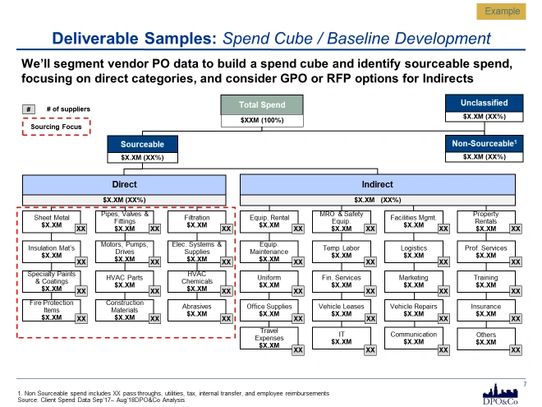

1. Combine & Conquer with a Spend Cube– the first and most critical step in this process is to get a firm grasp on what you’re buying, how much and from whom. To do this, segment your materials into related purchasing categories. In general, you can start with direct versus indirect and combine accordingly, similar to the example below (see figure 1):

Figure 1. Spend Cube Example

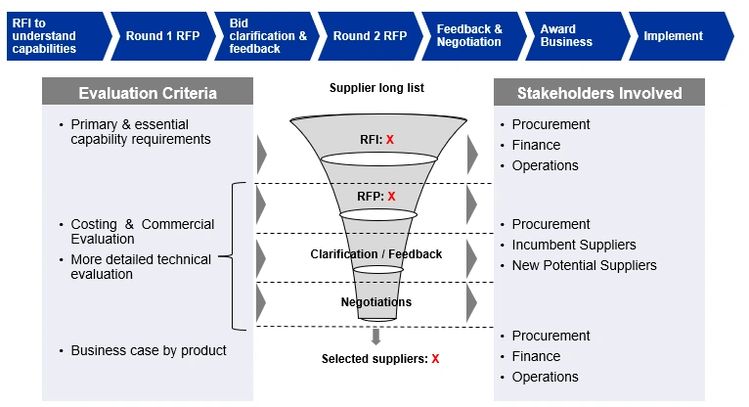

2. Follow a formalized RFP Process– next, you can conduct a rigorous process to focus on the true opportunities, conduct fact-based supplier discussions, negotiate options, and align on a go-forward path to reduce cost and complexity. This may trim the number of vendors earning business, but the relationships that remain will be more meaningful (see figure 2):

Figure 2. 7-Step RFP Process

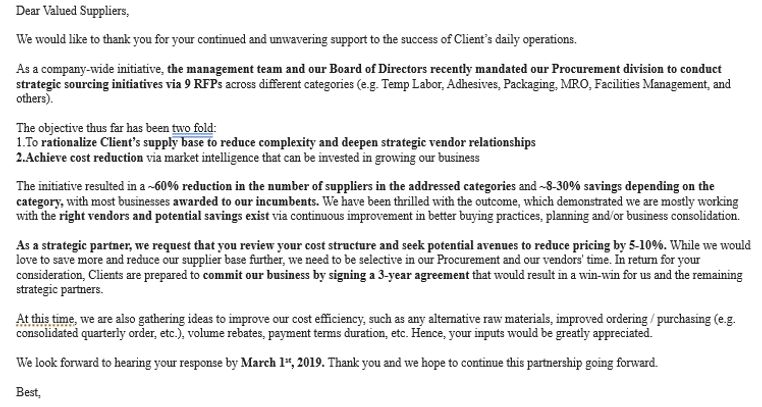

3. Request Savings from non-RFP Suppliers– certain items will not be included in the RFP process, as they are already single-sourced at the required quantities. However, due to the savings achieved in other spend categories, we can legitimately ask vendors to provide savings without issuing RFPs, by packaging it as a holistic supply-chain optimization project. We have issued letters like the one shown below (see figure 3) and realized savings, without formally conducting the RFP process:

Figure 3. Letter to Suppliers

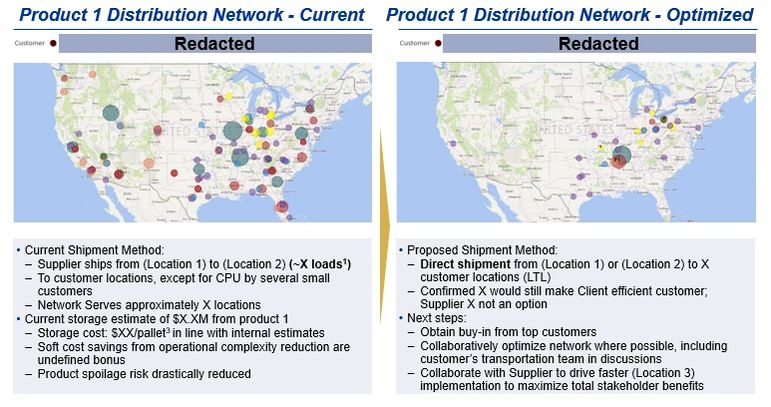

4. Optimize Client’s Supplier Network– lastly, there may be opportunities to simplify the supplier network, reducing costs, which get passed on to the client. For example, we have found opportunities to direct ship materials from the supplier to our client’s production sites, bypassing the distributor network and significantly reducing costs (see figure 4):

Figure 4. Supplier Network Optimization

The phrase “I’m a Procurement SME” probably never captivated an audience at a cocktail party, but having a robust sourcing methodology can significantly add value, whether post-merger or in a mature organization. DPO&Co can help you Combine & Conquer to reduce costs and complexity.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.